Sponsored article

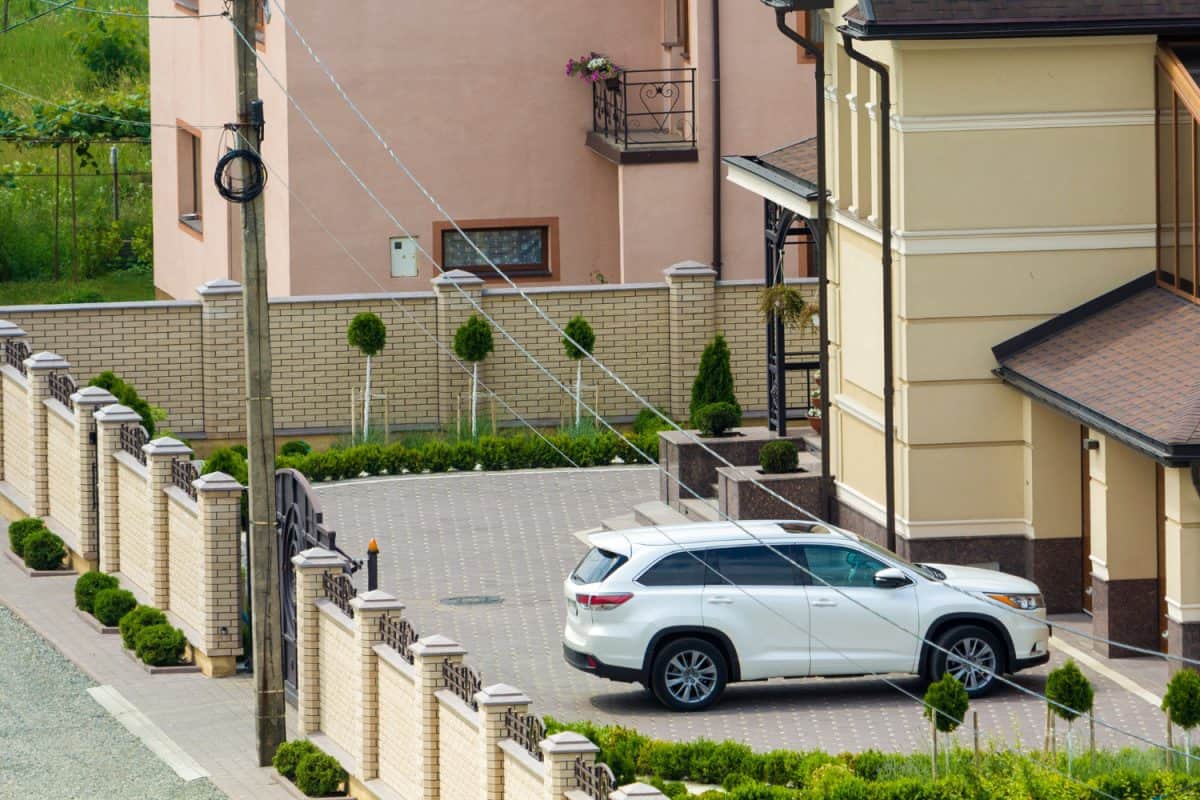

An even, smooth, and comfortable garage driveway is one important element that affects the health of your car. Your car travels on your driveway at least twice a day. This means that if it is uneven, it can damage the suspension, chassis, tires, or finish the shock absorption. A well-executed driveway is part of taking care of your car and, if you want your car to visit the mechanic as infrequently as possible, make sure it rides on a level surface, among other things. See how to make a garage driveway

Before you get down to laying paving stones on your driveway, you need to properly prepare the ground for the driveway to be there. The soil appears hard and compacted at first glance, but in reality, there are plenty of air bubbles and water in the soil. If a driveway stands on uncompacted ground, it will simply begin to sink and deteriorate over time. Before starting any other work, compact the soil thoroughly with a Wacker Neuson soil compactor. This will ensure a stable and solid base for paving or concrete screed. Uncompacted soil also means that there is a risk of cracking the concrete and creating protruding edges that can be fatal to your chassis. The hardened ground should be underlaid with a few centimeters of sand, which stabilizes the paving stones in the ground and prevents the elements from shifting.

If the area where you build your driveway is very wet or your cars are extremely heavy, it is worth making the substructure of more durable aggregate instead of sand. Typically, ballast, gravel, grit, cinder, and wedge are used because they are stable and readily available. If you opt for a substructure instead of a sub-base, you will significantly reduce the risk of your driveway collapsing in the future. In extreme cases, when the terrain is very waterlogged, yet another method of substructure is used – a concrete slab. Then, the driveway will definitely be stable and will stay in its place. This slab should later be lightly covered with sand in the same way as compacted soil so that the paving blocks have something to settle in and stabilize. NORWIT construction machines will certainly come in handy for all the work that goes into preparing a driveway

The actual laying of the paving stones is the easiest part. You will need a rubber hammer to drive the sett into the prepared soil. Why rubber one? An ordinary hammer is too hard and too heavy, so it can damage the paving block structure, cause discolorations or chips and the driveway will look unsightly. A rubber hammer is much safer for the paving, and it’s better not to take any chances, especially if you don’t have a large stock of paving blocks. The elements should fit tightly together and be laid evenly, there should be no empty spaces between them, because then the paving blocks will move under the wheels of the car

Put another layer of sand on the ready brick, in order to fill the joints between the elements. At the end, it is a good idea to polish the sett, so that its surface is perfectly even and looks aesthetically. A concrete milling machine will come in handy for this, as it will not only put sand into all missed joints, but it will also smoothen the surface of the paving blocks and make it look aesthetically pleasing